DMAIC – A Six Sigma Process Improvement Methodology

During my Six Sigma training sessions, frequently I come across some questions from participants-

- How should we start six sigma project in our organization?

- When should we start six sigma project in our organization?

- Do we wait for any customer complaint or any outside view about process issues?

- Is six sigma really applicable, as we don’t observe any process defect?

The philosophy behind six sigma approach is:

- Whatever we measure; acquires our focus

- Whatever we focus; leads to improvement

Hence, identify critical success factors for your business process. Define process metrics to measure process performance. With six sigma methodology, you can improve this process performance. Six sigma is a logical structured approach to improve business processes.

The Greek letter “Sigma” a statistical term; measures how much a given process deviates from perfection. Sigma is also known as standard deviation of the process from its mean. Six Sigma process enables an organization to measure the number of “defects” in a process, methods to eliminate them and get close to “zero defects” as much as possible.

Managers face challenges in improving the quality and efficiency of the business. To overcome, they need to implement the best methodology and tools to analyze and control the process. The best way to improve the result is to improve the process.

What is Six Sigma?

Let’s understand Six Sigma to get better clarity on this method.

Six Sigma is a measurement-based strategy for process improvement. It’s a methodology, which aims at improving process and increasing customer satisfaction (Both internal & external). The concept behind this approach is to reduce the variation in processes. This reduction leads to consistent and desired outcomes from processes. Hence, Continuous process improvement with low defects is the goal of this method.

Six Sigma Model (DMAIC Model) for process quality improvement:

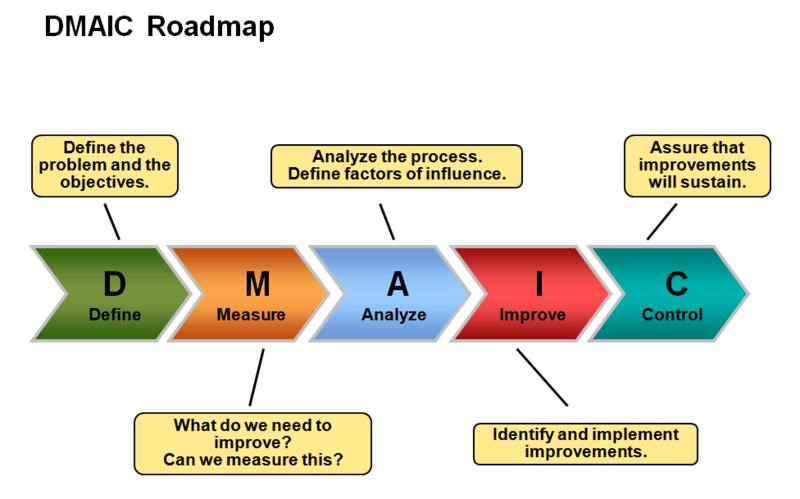

Six Sigma follows the DMAIC model for quality improvement and problem reduction (For existing processes). This well-defined process approach consists of five phases in order:

Image Source: http://businesscherub.com

Figure 1: Understanding DMAIC

- Define

- Measure

- Analyze

- Improve

- Control

It is an integral part of Lean Six Sigma process, but can be implemented as a standalone quality improvement process. Indeed, it is the most preferred tool that can help improving the efficiency and the effectiveness of any organization. Within the DMAIC framework, Six Sigma can utilize several quality management tools.

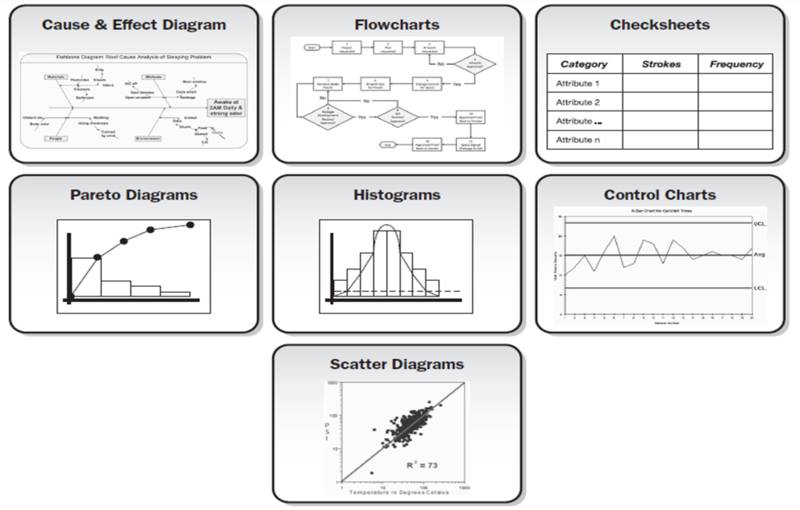

Seven Basic Quality Tools (Quality core tools):

Below is the list of some quality management tools, popularly known as seven basic quality tools –

- Cause and effect diagram or Ishikawa diagram

- Flow Chart

- Pareto Chart

- Histogram

- Check Sheet

- Scatter Plot

- Control Chart

These basic tools are helpful in six sigma projects at different times.

Image Source: https://takuminotie.com/english/2016/01/02/1-3-seven-qc-tools/

Figure 2: Seven basic quality tools

Now, let's discuss them to get better clarity and understanding:

1. Cause and Effect Diagram:

Also, known as Fishbone diagram. Attributed to Kaoru Ishikawa, the diagram has its shape similar to a fish skeleton. Hence, named as Fishbone diagram. This tool is used to explore causes to a single effect (or event) through brainstorming. These causes are put under different common categories known as 5 M or 6 M. Where, 6 M expands as – Man, Material, Method, Machine, Measurement & Mother Nature.

2. Flow Chart:

It suggests the process flow in a diagrammatic way. Outlines a pictorial representation of processes or process steps to understand their flow upstream or downstream.

3. Pareto Chart:

Also, known as 80:20 principle. Attributed to Vilfredo Pareto, Principle states, 80% of the outcome is a result of 20% causes. It’s a kind of bar chart showing the frequencies of different causes or factors in descending order. The main purpose of this chart is to highlight the most significant factors among a number of factors.

4. Histogram:

It’s a bar chart to study the frequency distribution of data set. It’s used to understand nature of data.

5. Checksheet:

It is used for data collection. A frequency of factorized data is collected in check sheet.

6. Scatter Plot:

Scatter plot represents the relationship between two variables. It shows, how one variable changes with respect to any change in another variable. Scatter plot can depict following relationships:

- Strong positive

- Strong negative

- Weak Positive

- Weak Negative

- Any trend (Parabolic)

- No relation

7. Control Chart:

These charts are used to check, whether process data remains under control for the shorter time span. They involve process control limits and sometimes customer specification limits as operational ranges or bands. Process data is analyzed to remain within process control limits. Whenever data goes out of control limits, it certainly has some special causes – to be investigated & removed immediately. The aim of these charts is to ensure process data doesn’t go beyond control limits. However, some exception rules are also there to ascertain the condition of a process going out of control, while well within control limits.

Describing DMAIC - each phase one by one:

Image Source: http://www.free-management-ebooks.com/news/six-sigma-dmaic/

Figure 3: DMAIC as a continuous improvement cycle

The process and tools associated with each phase are explained in following sections -

Define

The main objective of this phase is to summarize the project plan. This phase focuses on clearly specifying the problems; the goals of the process improvement project what is the scope of the project and identifying the customers (internal and external) along with their requirements. An input to this phase comes from the voice of customer (VOC), the voice of business (VOB) and/ or the voice of process (VOP). In addition, sometimes the voice of employees (VOE) is also effective to lead some six sigma improvement projects. With the help of these inputs, six sigma projects are identified. In this phase, we identify opportunity for six sigma projects. We develop a project plan and high-level process map. The main component of this phase is preparing Project Charter. Charter is a document, which is an initial blueprint for any six sigma project. It outlines following essential elements:

- Business Case: It helps to understand how the project is linked to the overall business objectives.

- Problem Statement: describes the problem or issue, this project is intended for.

- Goal Statement: defines the project goal by considering all elements of SMART. The acronym stands for Specific, Measurable, Attainable, Relevant & Time-bound.

- Project Scope: This considers in and out for this project. It defines the project boundary.

- Team & their broad responsibilities: Project team description along with their responsibilities and roles during the project.

- Time plan: Also, known as milestones. It ensures to keep a track on project progress as scheduled.

- Estimated project benefits: Project benefits need to be estimated as a deliverable. Cost-benefit analysis is conducted & benefits, both tangible & intangible are speculated. This gives a direction to top management, whether to approve the project.

Charter is duly signed & approved by top management. Thus, gives a signal to go ahead for outlines project from Top executive. Tools in Define phase are required to measure CTQ (Critical to Quality) characteristics. The Pareto Chart and SIPOC (Suppliers, Inputs, Process, Outputs, Customers) are the valuable tools of this phase.

Measure

The main objective of this phase is to collect the data that is relevant to the scope of the project. This phase focuses on identifying the parameters that need to be quantified, ways to measure them, collect necessary data and carry out measurement by different techniques.

The operational definition of metric is devised. It gives common language & understanding of data being collected. Data Collection plan outlines what data to be collected? When to be collected? Who will collect? Hence, sets overall direction for data collection.

After data collection, data is analyzed to ascertain its nature through frequency distributions. The histogram can be used to understand the distribution of data. Depending upon data nature – Normal or Non – Normal, data - analysis tools are decided. Current Process capability is also an important aspect to be understood in this phase.

In Measure phase, different tools can be used like Process flowcharts, Benchmarking, Run charts, Gage R & R and Process capability.

Two commonly used measurement techniques are – Defects Per Million Opportunities (DPMO) and Process Sigma.

Analyze

The main objective of this phase is to find the root cause of business inefficiency. It identifies the gaps between actual and goal performance, determine its causes and opportunities for its improvement.

Analyze phase follows a drill down approach to reach exact root causes from various potential causes identified initially.

This phase starts with exploring all possible causes to the main problem. Then, these causes are verified & validated though hypothesis & statistical tools. The outcome of this phase is verified root causes – which need to be acted upon to improve the process. Analyze phase requires due care to identify & verify root causes. Because the effectiveness of process improvement through six sigma project lies on the correct identification of root causes.

Commonly used tools in Analyze phase are Fishbone Diagram, Brainstorming, Histogram, 5 Whys, Hypothesis testing, Time series plots and Scatterplot.

Improve

This phase improves the process by determining potential solutions, ways to implement them, test and implement them for improvement. In this phase, process owners are consulted and improvements are suggested. Action plan for the improvement is circulated to relevant stakeholders. This action plan specifies – Action to be taken; By when By whom etc. The improvement plan is designed to mitigate the risk and include customer feedback and satisfaction. With the formation of improvement action plan, implementation phase starts simultaneously. During implementation, actions are carried out, tested for effectiveness and implemented finally.

Tools used to eliminate the defects are Brainstorming, Mistake-proofing (Poka Yoke), Simulation software, Prototyping, Piloting and Pugh Matrix.

Control

The main objective of this phase is to generate a detailed solution monitoring plan. This plan ensures that the required performance is maintained. It defines and validates the monitoring system, develops standards and procedures, verifies benefits and profit growths, and communicates to business. Hence, the main purpose of Control phase is to ensure – Holding the gains.

During this phase, post-implementation results are evaluated. Progress is ascertained. And Changes are incorporated - if any, correction or modification is required. Control phase in most of the cases is a transition phase. Transition happens from current practices & systems into new practices.

The most important part of this phase is to provide training on new changes to all relevant stakeholders.

Important tools used in control phase are Process sigma calculation, Control charts, Cost saving calculations and Control plan.

Six Sigma – A top-down approach:

Six Sigma needs a drive & support from top management to realize its full potential. Hence, it’s a top-down approach. Top management commitment is a key to success of Six Sigma projects. Six Sigma Master Black belts or Black belts should seek for the best possible management support to bring successful six sigma improvements. Apart from top management, commitment from all stakeholders and employees lead to exceptional outcomes. In the organizations, where six sigma is a part of organizational culture, excellence is pursued in each work area. Six Sigma approach is highly driven by the culture & values of the organization. The pursuit of continuous improvement & being excellent is an obvious buy- into six sigma applications.

Final Takeaway:

Six Sigma DMAIC methodology has been internationally accepted and can be implemented in small-size to high-profile firms. Six Sigma is highly structured & logical methodology. The structure followed passes through five important phases – DMAIC. The output from one phase is treated as input to next phase. And in the end, results are obtained as per expectations. All these five phases- define, measure, analyze, improve & control – form a circular chain of continuous improvement. Six Sigma is a quest – a journey for improvement doesn’t end by reaching one milestone. This process improvement tool can be used incessantly to realize continuous improvement. Hence, leading to excellence.

Be a part of excellence team by applying six sigma process improvement methodology in your organization. And improve bottom line profits & customer loyalty. Six Sigma will be rewarding to you and your organization.

Click Here for Six Sigma Course