What is the Annual Average Salary of a Six Sigma Certified Professional?

I hope you enjoyed reading my blog post on “8 Fatal Lean wastes-How to identify them?”! Now, we understand the criticality of Lean and Six sigma in today’s world! But… how does a lean six sigma career enhance my earning potential?

Well, in this article, I will share some information with you on this.

What Six Sigma certified professionals earn!

Indeed.com is the number 1 jobsite in the world available across 50 countries and 26 languages. It states that the national average salary for a Green Belt in 2016 is $83000 per year in the United States.

For Certified Black Belts, it is $99000 per year. For Certified Master Black Belts, it is even more at $121000.

According to data updated in January 2017 by payscale.com the median annual salaries for Green Belt Six Sigma Certified Professionals in the United States were:

| Job | Salary ($) |

|---|---|

| Mechanical Engineer | 75,873 |

| Manufacturing Engineer | 70,154 |

| Operations Manager | 80,753 |

| Process Engineer | 72,250 |

| Industrial Engineer | 65,187 |

| Production Supervisor | 62,446 |

| Quality Manager | 80,232 |

In the Indian subcontinent, the numbers stack is equally impressive.

| Job | Salary (INR) |

|---|---|

| Operations Manager | 951773 |

| Quality Manager | 1018255 |

| Mechanical Engineer | 660651 |

| Operations Team Leader | 469259 |

| Quality Assurance Manager | 1098837 |

| Assistant Manager, Customer Service | 609304 |

| Senior Mechanical Engineer | 866317 |

Did you know?

Six Sigma certified professionals are being sought after across the world. Honeywell, GE, Volkswagen and UnitedHealth Group are in constant search for six sigma certified professionals.

Certified professionals can be hired for a variety of positions within organisations -

- Lead Manufacturing Engineer

- Process Development Engineer

- Compliance Structural Engineer

- Reliability Engineer

- Lean Six Sigma Consultant

- Operating System Specialist

- Senior IT project manager

- Project Engineer

- Data Scientist

- Director/Manager – Operational Excellence

- Business Process Analyst

This is not an exhaustive list. Six sigma is integral to operational and manufacturing roles within all organizations.

Larger companies have a dedicated team of Six Sigma professionals. These teams work on a full-time basis in driving operations improvement strategies.

The full time ones fall into the following roles- let’s refresh our understanding on each-

- Master Black Belt (MBB): Expert in Six Sigma methodology and statistical tools. MBB provides strategic Six Sigma guidance and technical leadership within an assigned function in an organization. MBB is responsible for coaching, mentoring and/or training BBs. They lay down the training plans and project sign-off methodology within the organization. MBBs are a critical authority in signing off BB projects.

- Black Belt (BB): Full-time professional who leads Six Sigma projects. Trained in methods, statistical tools and team skills. Provides coaching and Six Sigma expertise to Green Belts.

- Green Belt (GB): May be a full-time or part-time role. GBs are 6 sigma project leaders capable of forming and facilitating Six Sigma Teams. They manage Six Sigma projects from concept to completion. Six Sigma BBs help GBs and assist them with their projects

- Yellow Belt (YB): Has a basic knowledge of Six Sigma. Support a GB or BB project as a core team member or SME.

Country-wide statistics of average salaries

Six Sigma as a philosophy has been an inspiration for thousands of organizations. This is despite companies operating in an unpredictable and volatile environment.

A recent Global Salary Survey conducted by iSixSigma, has once again emphasised this fact. The survey consisted of Black Belts, MBBs and other six sigma professionals. Two-thirds of the respondents are from the United Sates and 10 per cent each from Europe and India. Africa and Middle East respondents also participated, however, the scale was comparatively muted.

In Figure 1 below, Black belt salaries show a moderate increase to $84,643 worldwide. Quality Executives have the highest average salary of $140,153. Quality Professionals are earning at par with Black Belts.

Figure 1 – Worldwide Participation and Average Salaries (N=1190)

Image Source- isixsigma.com

The high salary of Quality Executives is not surprising. Majority of these professionals have 15 or more years of experience. Most of them have some level of Six Sigma certification as well.

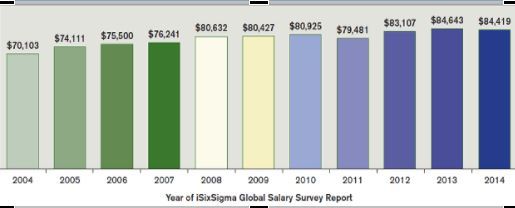

iSixSigma survey is being conducted since 2004. Per current research, average MBB salary is 42 per cent higher than the average annual BB salary (Figure2).

Figure 2 - Difference in Average Salaries for BBs and MBBs

Image source- isixsigma.com

Globally, MBBs reported an average annual bonus of $22,057 (Figure 3)

Figure 3 – Master Black Belt Average Salary and Bonus

Image source- isixsigma.com

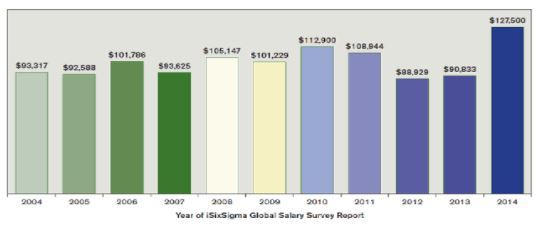

The 11th Global Salary survey by isixsigma.com shows some interesting trends. Look at figure 4 and 5 below

Figure 4 – Black Belt Worldwide Average Salary Year to Year

Image source- isixsigma.com

Figure 5 – Champion Worldwide Average Salary Year to Year

Image source- isixsigma.com

The Black Belt salary from 2013 to 2014 is stagnant. It remains to be seen if this trend is temporary. At the same time, Champion salary has dramatically increased during the same period. The number of data points being low, it is difficult to make any solid inferences from the data.

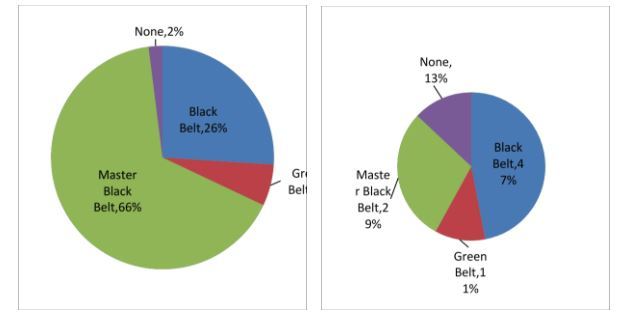

Figure 6 – Business Professionals by Highest Level of Certification

Image source- isixsigma.com

Figure 6 shows that 58 % of the Business Professionals are BB or GB-certified, while 29% are MBB-certified.

The trend shows certified Business Professionals increasing. This is further proof to the increasing criticality of six sigma certifications and roles in organizations.

Why is Six Sigma valued around the globe?

In today’s world, change is imminent. The difference, if any, is that the pace of change seems to be increasing with every passing year.

Management's job in an organization is to design systems. Systems that create and deliver value to customers and shareholders. This is a never-ending process. Competitors innovate in an attempt to lure customers. Innovations redefine the way products and services reach customers. Customer demands change at a lightning pace. What causes delight today becomes basic tomorrow.

The one factor that all organizations understand is “the change imperative”. Organizations that chose to resist change had to change or perished.

Lean and Six sigma embrace change. As a philosophy, it propagates continuous improvement in both quality and timeliness. Management has to come out with innovative techniques for product and service offerings. Operational improvement becomes behaviour rather than a set of initiatives.

Lean Six Sigma employs a structure and set of techniques. These act as a guide for managers to drive improvement within their respective areas. MBBs and BBs ensure to work along with the operations and production teams. This ensures clarity of direction and alignment of Six Sigma to business strategy.

To achieve this, there is a need for full-time Six Sigma Certified Professionals like MBBs and BBs. They help define and drive the strategy. They are responsible for training employees on their Lean Six Sigma projects.

Process owners support projects being champions for driving the initiatives. GBs and Yellow Belts (YB) work with their teams to ensure improvements and sustained.

What is the ROI for adopting Six Sigma?

So, what exactly does the organization gain by investing in a Lean Six Sigma approach?

Return on Investment compares the returns over time on total cost or investment. Six sigma adds huge value to any organization from a quality delivery standpoint. Lean ensures continuous process improvements as well.

At 2 sigma level or 69% defect level, the cost of quality (both good quality and poor quality) is 40% of sales. Processes generating sub-quality outputs escalate costs. Reduction or avoidance of cost of poor quality is a direct benefit of applying Six Sigma.

Returns can be hard and soft savings. Hard savings are cash savings. These result from waste reduction or headcount reduction. Soft savings are cycle time reduction or quality improvements.

The challenge with most organizations is to measure the soft savings. This is the non-cash yielding improvements.

Research by Invensis Global Learning Services shows that Lean and Six Sigma are the most recognized process improvement methodologies across the globe. Enterprises achieved 65% of higher project savings by adhering to Six Sigma methodology.

| Process Improvement Methodologies | Percentage |

|---|---|

| Lean | 50.02% |

| Lean Six Sigma | 48% |

| Business Process Management | 42.4% |

| ISO | 34% |

| Six Sigma | 33% |

Invensis research also quotes – an enterprise where on average an employee adheres to Lean Six Sigma, Process Improvement Methodology achieved 40% more ROI than those who did not use it.

Six Sigma Certifications

We already spoke about the respective Six Sigma roles including MBB, BB, GB and YB.

Six sigma levels are gaining popularity in different industries. Six Sigma professional roles are key to achieving breakthrough improvements and cost reduction. Each plays a significant role in the organization, irrespective of its size.

The following table provides a snapshot of Lean Six Sigma Black Belt courses offered by various institutes in India-

| GreyCampus | QAI Global | KPMG | Varsigma | |

|---|---|---|---|---|

| Accreditation | Accredited by IASSC | - | - | Accredited by Exemplar Global |

| Duration of training | 5 days, instructor-led classroom | 10 days, two phases, instructor-led classroom | 8 days, two phases, instructor-led, classroom | 6 days, two phases, instructor-led, classroom |

| Certification | Certificate by Greycampus (IASSC exam & certificate- optional) | Certificate by QAI | Certificate by KPMG | Certificate by Varsigma |

| Cost | Rs.17,000/- | Rs.48,000/- | Rs.60,000/- | Proposal-based |

| Training Material & Instructor support | One year e-learning access Lifetime access to all training material, hand-outs, tools and calculators | Shared documents like – articles, templates, calculators | Hardcopy of the training material for reference | "Hardcopy of Black Belt Book of Knowledge Preparatory module 15 e-books on Lean six sigma related content" |

| Additional Benefits | Learning aids like flashcards, downloadable e-books Simulated mock exams 45 PMI PDUs for PMI credential holders | Project support by experts for 1 year post training 70 PMI PDUs conferred on completion | - | Project assistance and support forum membership 24-hour minitab practice 54 PDUs for PMI credential renewal |

The following table provides a snapshot of Lean Six Sigma Green Belt courses offered by various institutes in India-

| GreyCampus | QAI Global | KPMG | Varsigma | |

|---|---|---|---|---|

| Accreditation | Accredited by IASSC | - | - | Accredited by Exemplar Global |

| Duration of training | 3/4 days, instructor-led | 4 days, instructor-led | 4 days, instructor-led, classroom | 4 days, instructor-led, classroom |

| Certification | "Greycampus (IASSC certificate- optional)" | QAI | Certificate by KPMG | Certificate by Varsigma |

| Cost | Rs.15,000/- | Rs.17,500/- | Proposal-based | Rs.16,250/- |

| Training Material & Instructor support | One year e-learning access Lifetime access to all training material, hand-outs, tools and calculators | Variety of articles and templates shared | - | Hardcopy of Green Belt BoK 10 e-books on Lean Six sigma related content |

| Additional Benefits | Learning aids like flashcards, downloadable e-books 3 Simulated mock exams Live online and Self-learning modules also available | Project support by experts for 6 months post training Recognized by PMI for 28 PDUs | - | Project assistance and support forum membership Sample question papers 36 PMI PDUs conferred |

With Greycampus, all the certifications are available in online self-learning mode as well. Post enrolment the student gets access to all training material.

For further details on course offering, duration and costs, refer to this link

- https://www.greycampus.com/lean-six-sigma-black-belt-training-instructor-led

Would you like to go for a comprehensive certification? Greycampus offers combo courses as well. So, within a rigorous program, the participant can achieve GB and BB certification. Refer to the link for course details

How does it help my career?

In today’s fast-paced world, all companies are vying for a share from the market. The larger the share, better are their chances of growth. Offerings on products and services change frequently on the basis of customer needs and demands.

Organizations invest fortunes in market research and innovation. Structured lean six sigma methodologies are a guiding force in this space. With a defined structure, six sigma helps companies to arrive at market-leading solutions.

The focus has shifted to design and use of DFSS (Design for Six Sigma) methodology. This has further potential, when it comes to new product introduction.

Six Sigma guides managers to define what customer needs supported by a set of measures. What gets measured, gets improved!

Lean focuses on the process and builds a culture of continuous improvement. Hand in hand, lean six sigma techniques are indispensable in organizations today.

Are you a quality personnel in a manufacturing or service organization/function. Lean six sigma certification helps you build yours skills and learn new techniques. It also gives you a knowledge base to train your teams on the skills as well.

Are you an operations/service/production manager in an organization/function? Lean six sigma certification helps you enhance your understanding on measures and techniques. You can train your team members on effective problem-solving techniques.

Are you looking for growth within your current organization? Or are you looking for opportunities outside? Lean Six Sigma certification gives you an edge in the competitive marketplace.

As a career interest if you wish to pursue your own business. Lean Six Sigma professionals are sought after by organizations as consultants and trainers. A certification might be the beginning of your career as a business person.

In a nutshell…

Six Sigma certification opens a plethora of opportunities for fresher’s and working professionals.

The demand for Lean Six Sigma professionals will continue to increase. Organizations need to innovate and thrive in today’s fast-paced business environment.

Embark on this fulfilling journey. Begin with certification and explore the unlimited opportunities this space has to offer.

Find the next course near you!