How to Deliver Customer Value and Reduce Waste with Six Sigma

The utility of Six Sigma culture boils down to a few crucial aspects, and reducing waste while enhancing customer value is among the obvious ones.

In Six Sigma parlance, customer value is the need of the customer and the worth of the service or product the customer is willing to pay. Irrespective of the expertise of the Six Sigma professional, it is the customer who is the final authority when it comes to determining the value. Deviations in the effort or any additional effort put in toward delivering the value is waste.

Closely linked to value in Six Sigma is the concept of VOC, or Voice of the Customer. The customer’s specific needs and expectations from the product or service are known as the voice of the customer. Six Sigma professionals are an asset to any organization. Among their various skills, what’s more important is their ability to listen to the VOC and drive the project with VOC as the proverbial light at the end of the tunnel. This is how you, as the Six Sigma professional, can deliver customer value and also reduce Six Sigma waste.

Ascertaining Value

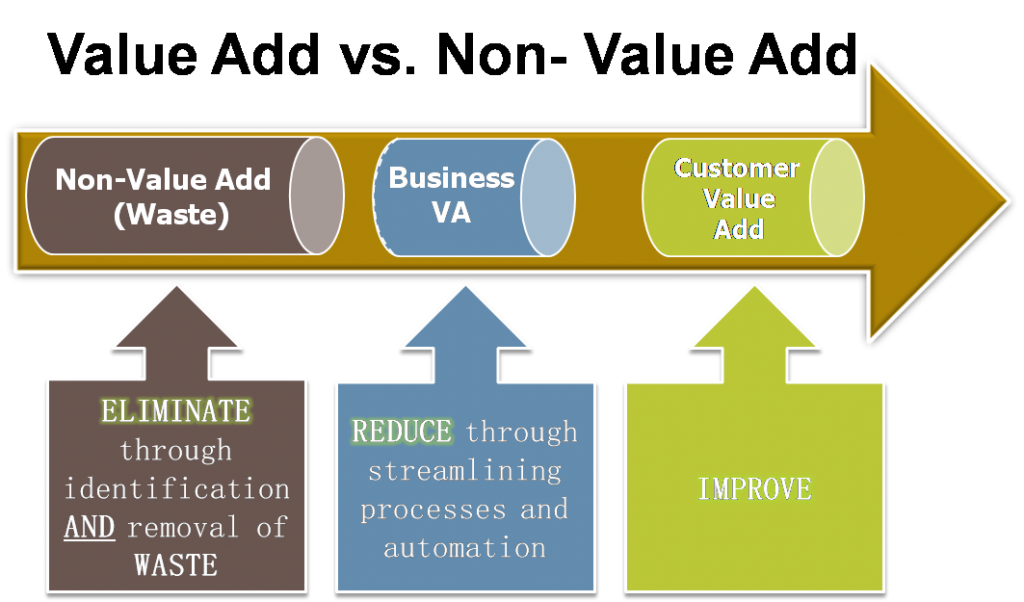

Since you are not the one deciding what is value, there is always a risk that what you think is value may turn out to be a waste. And waste is not unheard of in Six Sigma, as most of us know. Added values are the steps and activities that actually add customer value. But there are steps, activities or product features that do not end up adding value and are known in Six Sigma as non-value add or NVA. NVA is an example of the many concepts that make methodologies like Six Sigma and Lean universally relevant.

Source: Jennifer Goldman Consulting

Six Sigma practitioners follow a mechanism of constant feedback and change to ensure that what they are doing is of true “value” for the customer. You can ascertain value in your work by ensuring three things and getting all these three things right.

- Does the task or feature you’re putting into the item change the item itself in any shape or form?

- Once you add the feature or improve a step, does the effect of the addition or activity reflect in the item or service in the correct manner?

- Is the customer happy to pay you for this new step, activity or feature you performed or added?

If you can’t answer all these three questions in the affirmative, there is no way your feature or process is adding value.

How to Identify Non-Value Adding Waste Using Six Sigma?

You know so far that three key questions ascertain the value and identify waste and a non-value add activity or feature. However, to further ease the pursuit of identifying NVAs in time, NVAs are divided into seven categories. Any effort or feature falling into one or more of these seven categories can be waste, and it’s necessary to act accordingly.

Shortened as TWODIME, let’s look at this non-value-adding waste commonly identified in Six Sigma.

1) Transportation – The movement of a component or information is waste, even if the movement occurs to ensure the continuation of the process. While a change in the latest position can add value, transportation merely facilitates the change. So, it doesn’t add any value on its own and is a waste in Six Sigma terms.

2) Waiting – If a resource is undergoing bench time or the process or equipment stands still, it is a clear case of waste. This is true not only in Six Sigma but in any given scenario. Waiting doesn’t add any value to the Six Sigma project and is an outright waste.

3) Overproduction – Overproduction may not seem like a direct waste, but there are elements of waste in it. You may overproduce for some genuine reason, to meet the future need for instance. While it may seem proactive to be prepared for the future, overproduction locks up inventory and may result in waiting time, consequently, the possibility of wastage in overproduction.

Source: Muhammad Mubashir Ghori

4) Defects – If the efforts or materials result in the production of defective output, the entire endeavor is a waste. The output in these cases needs a rework or to be scrapped entirely. As efforts are put in to either correct the output or create a new one, the original and defective steps/materials are waste.

5) Inventory – Inventory takes up physical space and ties up working capital. Managing inventory requires money and effort as well. These inventories could be raw materials waiting for processing, items rolling down the production process, or finished inventory that is waiting for shipping. Backlogs of information are also an example of inventory. All these types involve a cost, and in their current form are a waste.

6) Motion – Somewhat similar to transportation, motion is the movement of people, equipment or product in the course of regular activity. While transportation is a necessary movement to ensure the production process, or a shift from one process to the next, motion is often unnecessary. It can also be an undesired or potentially harmful movement as well, leading to a high Six Sigma defect rate or other wastage.

7) Extra Processing – It is that part of an activity that is not part of the product feature or something that the customer is ready to pay for. Extra processing is the additional processing that an activity undergoes but doesn’t yield a corresponding revenue output. Going the extra mile can lead to waste.

How to Deliver VOC Using Kano’s Framework?

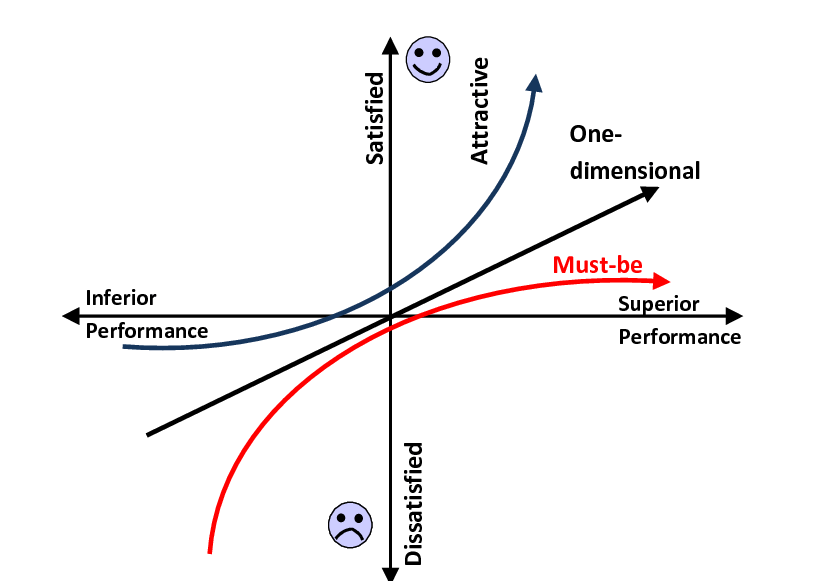

Japanese engineer and quality thought leader Noriaki Kano came up with a framework to define VOC. He built this framework on the premise that there are different levels of customer satisfaction. Graphically represented, the Kano framework plots the level of your accomplishment against the requirement in the horizontal axis. The vertical axis represents how satisfied a customer is with your product or service.

So, as you achieve more of the customer value, you move to the right side of the horizontal axis. If you also achieve customer satisfaction along the way, your position will be in the ideal upper right quadrant of the Kano framework graph.

Source: ResearchGate

Where Kano’s framework standouts are the interpretation of customer value and requirements in three distinct categories.

Needs are the obvious outputs that a customer expects from your product or process. Achieve the customer value and the customer satisfaction will be neutral because this achievement is something expected of you anyway. Not fulfilling it is, however, certain to lead to customer dissatisfaction.

Wants, on the other hand, are the customer requirements that move in direct proportion to their achievement or failure.

Delighters are the unexpected outputs that can tip customer satisfaction heavily in your favor if you manage to achieve them. These are not apparent customer values, and the customer doesn’t care if you don’t achieve them. Delighters are the quick wins you can identify and achieve to ensure substantial business success.

How Can You Create a Six Sigma Culture That Delivers Customer Value

How employees work is the reflection of the organization’s culture. Employees are likely to integrate and implement Six Sigma in their work more if the company itself promotes a Six Sigma culture.

The benefits of Six Sigma and its implementation in the company culture should be visible. This also requires bringing in a change in the employee mindset. Six Sigma principles should be seamlessly integrated into the organization. The role of the top management is crucial in this regard. Management should redefine policies to accommodate the Six Sigma way of functioning. Championing Six Sigma and its adequate communication internally helps in creating the Six Sigma culture.

It is a given that Six Sigma training is an obvious route toward creating a Six Sigma culture in the organization. The case studies and examples that follow the training allow a real-life simulation of Six Sigma culture in the workplace and stabilize the new work culture.

Learn Lean Six Sigma with GreyCampus

When it comes to training the employees in Six Sigma, GreyCampus is a prominent name in the academic sector. GreyCampus provides Lean Six Sigma Green, Yellow and Black belt training and certifications that provide industry-best study modules and plans. These certifications also provide unlimited access to live bootcamps, which certified and some of the best Six Sigma instructors in the industry lead. Bootcamps can be immensely beneficial for anyone looking to add Six Sigma to their profile or work culture.

Packed with access to audio-video lectures, practice questions, exam-solving sessions and simulated tests, the GreyCampus Six Sigma programs are the ideal steppingstone for companies and professionals to enhance Six Sigma adoption in their work culture.

A GreyCampus Six Sigma certification definitely adds value to your professional profile, so reduce your waiting waste by going ahead and enrolling for the course relevant to you.

Want To Reduce Waste With Six Sigma? Join a Bootcamp Today!