Lean Six Sigma Helps Fleets Keep Moving

Making Fleets move faster off the roads too: Using Lean Six Sigma Tools and techniques to keep the fleet vehicle moving!

Several fleets employ an array of Lean Six Sigma (LSS) tools to reduce costs of operations. They use it to improve the predictability of available vehicles and formalize business processes. They also use it to create high standards for repairs. Many fleet operations are familiar with standardization. They understand Lean Six Sigma is not a training program for manufacturing. Not long after LSS concepts were identified to assist manufacturing, service operations began to use these tools and techniques. Lean Six Sigma's production-related principles apply to fleets. Fleet Maintenance and repair processes in fact involve production, not only value-add service. When you move vehicles from needing a repair to repair completion it is “Work in Progress” to “Ready to ship”.

The DMAIC methodology that LSS offers.

Fleet operation now uses LSS as a management strategy to improve process quality. They use a lean Six Sigma process to identify the root causes of errors and variability in operations. In doing LSS projects, you can improve the efficiency of your business operation. In this case, you improve your fleet of vehicles. An LSS project follows a defined sequence of steps. The type of project determines the sequence of steps (DMAIC v. DMADV). DMAIC is to change an existing process.

Some of the ways a fleet may use LSS tools are below. They use a tool such as a Run Chart to check a small problem. You can then verify if it is getting worse over a period of time. Deploy a Value Stream Map to determine if the current steps are necessary. You determine which add value and which do not.

Often, these are small projects that do not take long to execute. These small projects can have a large impact on your fleet operations. Projects also allow participation from personnel. Participation can often be critical to buy-in and long term success.

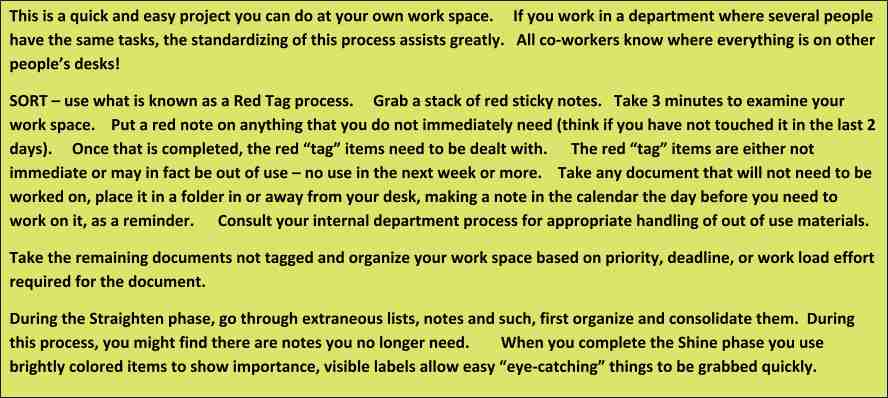

An essential process for getting a workspace or work area organized is 5S. 5S is helpful in maintaining the organization and cleanliness of a workshop area. 5S stands for Sort, Straighten, Shine, Standardize, and Sustain. It comes from a Japanese concept for housekeeping. Some fleets I have worked with also incorporate a sixth “S” – for Safety; thus the +1.

- “Sort” is moving the everyday tools and hardware to a preferred location. You remove irregular ones for storage elsewhere.

- “Straighten” means you put these items in a bin for easy identification. You locate these bins and storage in actual work areas. This will cut the steps by technicians on day-to-day tasks.

- “Shine” means you clean an area (and keep it clean). Place warning signs in visible areas – you also incorporate this into safety.

- “Standardize” is when the team develops and documents any and all processes. The team can place a process that affects everyone on wall placards for visibility. To help “standardize”, some fleet repair operations will create bins for the top 3 to 5 common repair jobs. In the bins, they show the hardware/tools needed for the job. This eliminates extra steps (refer here to waste) that an inexperienced tech may take. This might be because they forgot something needed for that repair. When an operator uses standards, it allows the garage to maintain the first 3 “S” categories.

- “Sustain” will rely on discipline, to stick to the rules. It can cultivate a sense of encouragement from the whole team.

The team can incorporate the plus 1 - “Safety” - with extra steps like visible safety tape on floors. This shows the safest (and most efficient) path to tools and hardware. You can also locate safety equipment throughout the facility for easy access. Harmful materials are set in a designated area with plenty of signage.

Making use of The Pareto Principle

Another way that fleets are adapting LSS techniques is by using a Pareto analysis or chart. Use a Pareto Chart when a fleet has many repairs or a common repair with several root causes. A fleet manager can observe past repair orders, for the previous year. Then chart the problems to determine their frequency of occurrence. The manager has the information to focus on work effort. The manager can give priority to tools and hardware a fleet will need in its inventory for the next quarter. Think back to the 5S. This analysis shows the common repairs. A garage can create the bins and ensure it has the appropriate number of tools/hardware needed. Pareto Analysis uses the classic 80/20 rule.

It is often the case that 20% of the repairs result in 80% of the costs to maintain vehicles.

A common technique that organizations use a Lean Six Sigma approach is solving a problem. With a fleet, it is often a common repair (use Pareto Analysis to determine these repairs for a fleet).

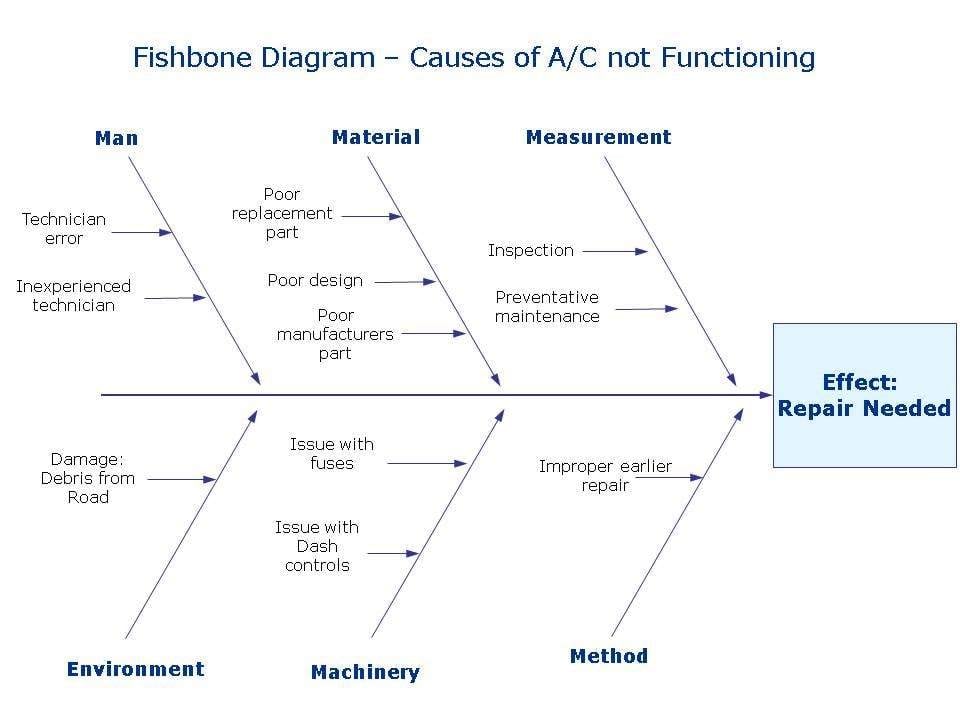

A Fishbone Diagram for the Fleets

One of the easiest problem-solving approaches is a Fishbone Diagram. It is also called a Cause and Effect, or Ishikawa diagram. This is a way to identify the root causes of repairs. I often couple the Fishbone categories with a 5-Whys approach for the causes. A team brainstorms possible causes within a specific event. The team will analyze the following categories:

- Measurement

- Material

- Man

- Method

- Machine

- Environment

One by one, the team works through the list; to prove or disprove each cause listed. Brainstorm to name every possible cause. They categorize them into a broad/universal reason. The team will reduce each reason again and again until you isolate either an outcome. Fishbone diagrams get their name from the design of the frame resembling a skeleton for a fish.

Once the brainstorming sessions are over, you can then isolate the issue as follows:

A fishbone diagram allows your team to go through the individual steps that led to a problem or a repair. Let's use an example of a driver complaining an air conditioning unit is not functioning in a vehicle. There are several possibilities for the cause. In using a fishbone, you break the problem down into the previous categories. One of the creative things about a Fishbone is that it allows for brainstorming activities. To will foster a team-oriented project environment – push your out-of-the-box thinking.

I also work with fleets to ensure a Lean Six Sigma process to apply protective coatings on their vehicles. Coatings provide protection from elements and help to prevent corrosion. The use of Six Sigma in a process will reduce variation and eliminate errors. In a coating application, errors occur when there is a variation in the process. Different designs from vehicle to vehicle or different technicians applying the coating. The protective coatings are on vehicles to prevent corrosion.

Thus, an area that is “untreated” is a defect. We create a process using the same chemicals and apply them to the same areas on different designs. Use a standard process that is easy to follow and scalable for the different vehicle designs. We ensure that the fleet will apply the coatings in a correct and efficient manner. This allows the fleet to standardize its vehicle audits and preventive maintenance schedules. The standardization creates less tact time needed during audits as well.

Workers coating galvanized paint on the hull of the ship

An effective audit is valuable to analyze drivers, mechanics, and performance of a fleet. The measures include the specific unit cost to a piece of equipment. It can also be a comparison of maintenance costs versus total maintenance costs. This analysis provides information on vehicles. The information includes availability, use, and efficacy of labor and turnover rate.

Conclusion

With these techniques, a fleet maintenance operation can realize savings on inventory. This can provide less downtime for vehicles and an increase in operating efficiencies. A fleet can use Lean Six Sigma as a measuring tool for time spent on many things. These include work orders, shift changes, and overlap of shift changes. Soon after the concept of Lean Six Sigma appeared, many realize that it is not only for manufacturing. I find it does work best and is a very good tool for a learning organization.

.jpg)

Think about fleet management operations for a moment. Managers often complain about the high percentage of time spent in rework. What does that constant rework cost an organization? This is a chronic problem and is common in fleets. Lean Six Sigma techniques can give you the proper tools to solve that problem. It can reduce the variances and eliminate waste (errors). Any mechanic knows you need the right tools to do any effective work!

Become a certified Quality Management Professional.